Scientists have just demonstrated how to 3-D print flat timber to ensure that it later on changes into a wanted complex shape. The trick: They count on what could have been a challenge– the propensity of moist timber to warp as it dries out.

This exceeds just 3-D printing, states Shlomo Magdassi. He examines nanochemistry at the Hebrew University in Jerusalem, Israel. His group publishes things that transform with time or in action to something. That transforms this right into four-dimensional– or 4-D– printing.

Explainer: What is 3-D printing?

Plants inspired the job, notes employee Doron Kam, who additionally works at the Hebrew College. Some seedpods diminish, twist and divide open as they dry out, spilling their freight. That twisting activity is due to how the pods’ woody fibers align at the tiny degree. Which, Kam states, “we can simulate.”

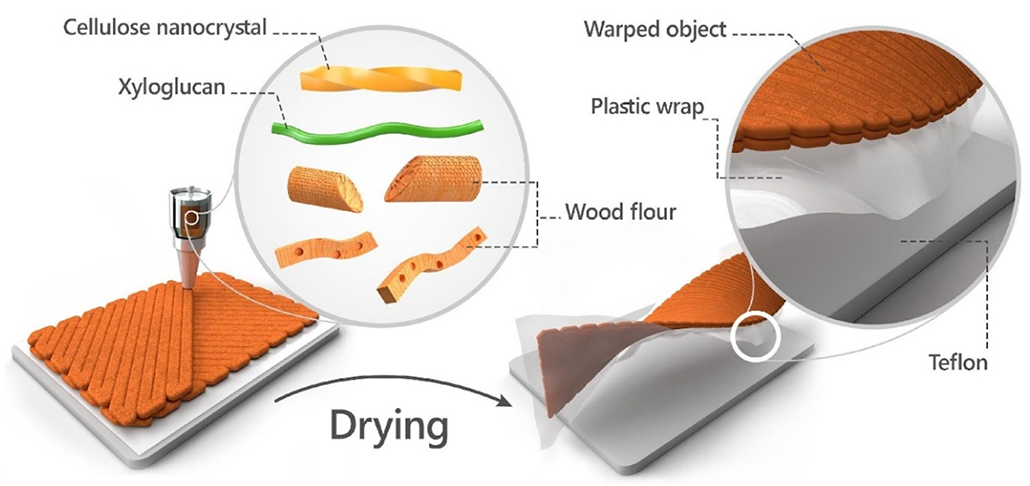

The researchers initially had to determine just how to make timber fibers line up in desired means. To do this, they relied on ground-up timber, referred to as wood “flour.” They dampened it right into a paste to make the ink for their 3-D printer.

The team published their forms at different speeds and also using different patterns to lay down the ink. After each examination, Kam states, “We aim to see exactly how it dries.” In the process, they learned how to 3-D print a self-morphing, seedpod-like framework. They defined their technique in the February 2022 problem of Polymers.

They supplied a lot more information about just how to regulate the shapeshifting of wood ink on August 23. They were presenting their operate in Chicago, Ill., at the autumn conference of the American Chemical Culture.

they deformed into these shapes.Kam et alia/ Polymers 2022 (CC BY 4.0)Whoa, decrease! Publish speed, the team discovered, plays a huge duty. Rapid printing causes a flat strip of printed wood ink to curl tighter as it dries. Slower printing leads to looser curls. Why? Swiftly laying down the ink makes the woody fibers line up straighter, Kam explains. And that changes how they contour as they dry out.

Likewise crucial was the direction an ink was put down. For instance, a flat disk printed with concentric circles will warp differently from a disk printed from straight lines. Taken together, such elements permit engineers to set the shape of the dried object.

great to see that they looked likewise right into the result of gravity in the total shape adjustment,” states André Studart. If you want to print large frameworks, he states, that’s important. He’s a materials researcher at ETH Zurich in Switzerland. Studart also likes that the ink originates from “timber waste”– not lumber. That indicates no trees were logged for these products.

Athanasia Amanda Septevani additionally likes that. This products researcher keeps in mind there are lots of wastes that could discover brand-new uses this way. Take into consideration the palm-oil sector. Septevani works in India at the National Study and Innovation Firm in Indore, Madhya Pradesh. The fruit of palm trees in Indonesia, where she matured, are crushed to make oil. Each lots of hand oil produces regarding one lots of plant wastes (in the form of empty palm fruits and crushed kernels). “The waste is massive,” she states. Yet the new research points to the worth in locating usage for such wastes.

The brand-new ink is made from timber flour and “a sort of glue,” Magdassi says. Even the glue comes from timber wastes. These are nanocrystals– “really small, needle-shapes of cellulose,” Septevani explains. Cellulose, she explains, likewise makes up around 40 percent of palm-oil wastes.

Cellulose nanocrystals in the ink “allow us to utilize much less water,” says Kam. That provides much better control over the form that printed wood will certainly take as it dries out.

al/ Polymers 2022(CC BY 4.0) Still a work in progress

Kam wishes this modern technology can alter the way people develop points. Many producers attempt to make points– “like a block”– that last as long as possible, he says. But that’s not just how nature functions. Microorganisms expand, die as well as rot. This allows their foundation to be recycled to make new organisms.

His team’s products likewise are reusable. Says Kam, you can “take any kind of old wood.” Probably an old chair or room dresser. Instead of trash it, grind up its wood and also reuse the sawdust– flour– to make something new.

Kam really hopes that a person day, we won’t carve up our trees to make new chairs however rather just 3-D print a new one. “You sit on it for 3 or four years,” he states. When you tire of it, just grind it up and print something new.

This is one in a series providing news on technology and innovation, made possible with generous support from the Lemelson Structure.